Peak performance starts with digitalization.

Digital solutions

use smart technologies, advanced analytics, and artificial intelligence to identify

opportunities

for improvement, making data-driven decisions to

enhance

performance.

What does that mean?

- Increased productivity

- Improved decision-making

- Reduced operator involvement

- Streamlined operations

- Higher return on investment

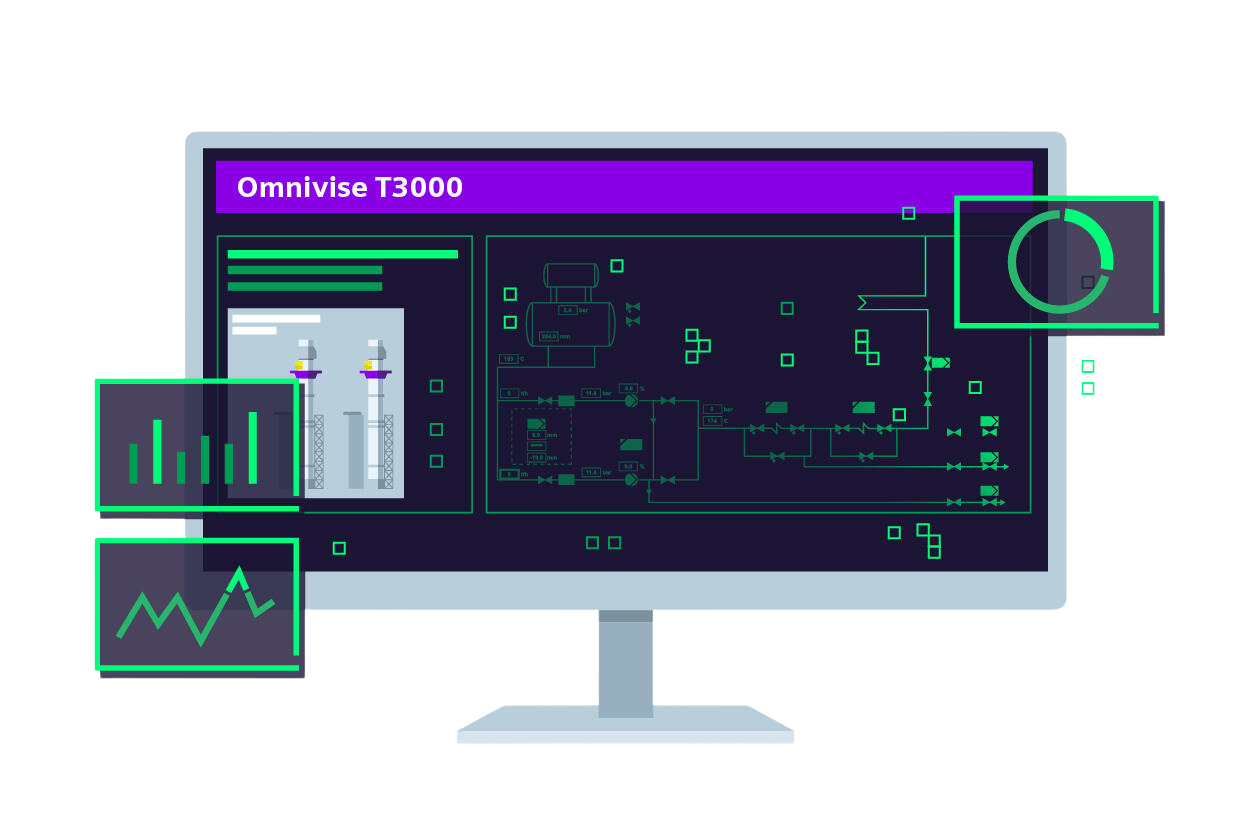

Peak performance starts with Omnivise.

What is Omnivise Performance Management?

A suite of digital offerings engineered to maximize the performance and financial yield of your plant.

How does it work?

Using advanced technologies, such as data analytics, artificial intelligence, and digital twin simulations, Omnivise Performance Management helps operators optimize performance while minimizing operational costs to deliver low-cost, high-quality energyto customers.

What will you gain?

Up to

72-hour

Operation without supervision

Increased

Transparency and data-driven decision-making

Increase

Power production by Turbine Modifications / Upgrades